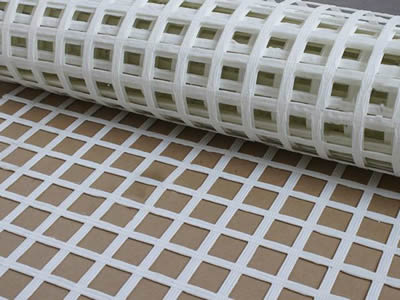

Composite Mine Supporting Mesh - High Tensile Steel Wire and Plastic Surface

CMSM-01: Composite mine supporting mesh has high strength and anti-flame and inflaming retarding.

Composite mine support mesh is an new popular type. It is widely used as geogrid in the road constructions before. It is made by reinforced mesh belt containing high tensile spring core wires and PE or PP surface material. The steel and plastic reinforced mesh belts are attached to form a high strength and durable meshes with coarse vein surface. The coarse vein surface can make the supporting mesh being attached to the roof or sidewall firmly. Additional, it can increase the friction coefficient between supporting mesh and roadway sidewall and roof.

Compared with bilateral stretched plastic supporting mesh, the composite mine supporting mesh has higher tensile strength and breaking strength. Additional, it is inflaming retarding and anti-static, which is superior to the steel wire mine supporting meshes.

Composite mine supporting mesh has not only the high tensile strength and breaking strength of steel wires, but the high corrosive and anti-flame performance of plastic meshes, it is an ideal choice for roadway roof and sidewall supporting meshes.

Specifications of steel plastic composite mesh

- Material:

- Core wire: high strength steel.

- Surface material: polyethylene or polypropylene.

- Mesh size: 30 mm × 30 mm, 40 mm × 40 mm.

- Roll width: 0.8 m – 3 m.

- Roll length: 5 m – 50 m.

- Color: white and black. Other colors can be customized.

CMSM-02: White color composite mine supporting mesh.

CMSM-03: Black color composite mine supporting mesh.

Features of steel plastic composite mesh

- Low ductility. It can maintain the flat and smooth surface in high pressure.

- Corrosion resistance. The surface plastic coating protection can help steel plastic composite mine supporting mesh from corrosion and rust.

- Lightweight. It has about 1/3 weight of steel wire mesh used as coal mine supporting mesh, which is convenient for transporting and using.

- Cut into pieces. The steel plastic composite mine supporting mesh can be cut into any size and the structure will not loose.

- High tensile strength. The high strength steel wires and plastic surface supplies double tensile strength than the common steel supporting mesh.

- High stability and firmness. The advanced adhesive technology makes the composite coal mine supporting mesh withstand the high impact and the structure will not loose.

- Good flexibility. It can make the construction easy operating and high efficient.

- High safety. Inflaming retarding and anti-static to ensure the safety construction.

CMSM-04: High strength steel wire and solid plastic supplies high tensile strength.

CMSM-05: Advanced adhesive technology make the composite coal mine supporting mesh a firm and solid structure.

CMSM-06: Composite mine supporting meshes are commonly supplied in rolls.

CMSM-07: Woven bag at both ends package.

CMSM-08: Composite mine supporting mesh in woven bag package.

CMSM-09: Woven bag can protect composite mine supporting mesh from corrosion during transporting.

Related products

- Welded wire mesh. Steel wire or reinforced bars for solid and high strength protection.

- Chain link mesh. Flexible and soft structure for roadway roof and sidewall protection.

- Crimped wire mesh. Crimped and woven structure for coal mine tunnel security.

- Woven wire mesh. Simple but high tensile strength woven structure for security.

- Bilateral stretched plastic mesh. Bilateral stretch supplies even meshes and high strength to mine roadway roof and sidewall.

CMSM-10: Welded wire mine supporting mesh.

CMSM-11: Chain link mine supporting mesh.

CMSM-12: Woven wire mine supporting mesh.

CMSM-13: Bilateral stretched plastic mine supporting mesh.

CMSM-14: Crimped wire mine supporting mesh.